Automotive

André has an important presence in General Industrial and Automotive segments.

Automotive coatings are used on automobiles, trucks and agricultural machinery for protection and decoration purposes.

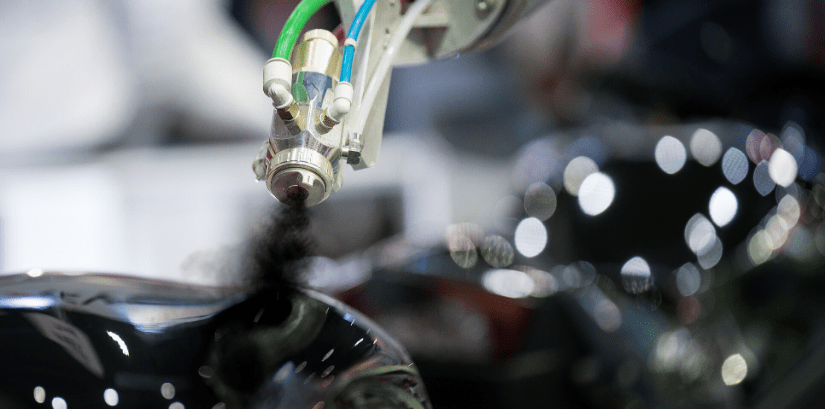

In the early days of the automobile industry, paint was applied manually and dried for weeks at room temperature because it was a single component paint that dried by solvent evaporation. As mass production of cars made the process untenable, paint began to be dried in ovens. Nowadays, two-component (catalyzed) paint is usually applied by robots.

Until several decades ago lead, chromium and other heavy metals were used in automotive paint. Environmental laws have prohibited this, which has resulted in a move to water-based paints. Water-based acrylic polyurethane enamels coatings are now almost universally used as the basecoat with a clearcoat.

The automotive paints are not delivered as finished end products, they are applied in several layers.

The car body is dipped into the Electro-Coat Paint Operation (ELPO/E-Coat), then a high voltage is applied. The body works as a cathode and the paint as an anode sticking on the body surface. It is an eco-friendly painting process.

The primer is the first coat to be applied and it serves several purposes.

- It serves as a leveler, which is important since the cab often has marks and other forms of surface defect after being manufactured in the body shop. A smoother surface is created by leveling out these defects and therefore a better final product.

- It protects the vehicle from corrosion, heat differences, bumps, stone-chips, UV-light.

- It improves ease of application by making it easier for paints to stick to the surface. Using a primer, a more varied range of paints can be used.

The base coat is applied after the primer coat. This coat contains the visual properties of color and effects, and is usually the one referred to as the paint. Base coat used in automotive applications is commonly divided into three categories: solid, metallic, and pearlescent pigments.

Usually sprayed on top of a colored basecoat, clearcoat is a glossy and transparent coating that forms the final interface with the environment. For this reason, clearcoat must be durable enough to resist abrasion and chemically stable enough to withstand UV light. Clearcoatcanbeeither solvent orwater-borne.

The total thickness is 0.1 mm (varies among the producers)

Our Product range in this segment:

Automotive Industry, which means Passenger Cars, Bus Body shop, CycleIndustry, Engine Industry, 2 Wheelers – Scooters, Motorcycles and mopeds.

- Pretreatment Chemicals

- Water Based Primers

- Polyurethane Paints

- Polyester Top-Coats

- Epoxy Surface

- AED

- Easy to Clean Surface

- Quick Drying Coatings

- IR Reflection

- Isocyanate Free

- High Performance Clearcoats

- Anaerobic Sealants