Military

Ammunition coatings, external sealants and dispensing solutions

André Industrial has been developing ammunition coatings and external sealants for small and medium caliber ammunition in close cooperation with our international customers for many years. Hundred of companies from some 80 countries produce small and medium size caliber ammunition and trust Andre as world leader and registered Nato contractor. Ammunition external sealants against water and contaminants, for a higher pull-out strength and improved ballistic precision. Our international customers appreciate us as a preferred development and product supplier who provides application specific solutions flexibly and reliably.

The ammunition coatings, ammosealing, ammunition external sealants and munition adhesives are continuously being researched in cooperation with universities, institutes, most of the ammunition machine producer and certified according to the German Bundeswehr (according TL8010) and the NATO.

We can assure our customers that no modifications in view of the availability or other conditions with respect to our products and suppliers may be expected from the REACH regulations.

Product overview of ammunition coatings and external sealants.

- Primer groove varnish in the colour red, green, blue, black

fluorescent for optical inline control as option - Case mouth varnish, bituminous based (water and solvent based)

according Nato standards - External sealants, anaerobic and UV cured in different colours, fluoresces for optical inspection control

- Interior varnish with high chemical resistance (TL8010-0022).

- Bullet topcoat and blank ammunition

- Antifriction varnish, antifriction characteristics for better ballistic and protection, especially for steel cartridges

Ammunition coatings for small caliber ammunition.

Small caliber ammunition demands high material requirements on waterproofing, sealing, anticorrosive protection, bullet pull-out strenghth and the shelf life of the ammunition.

The range of products offers a wide variety of interior ammunition coatings, exterior ammunition varnishes and external sealants.

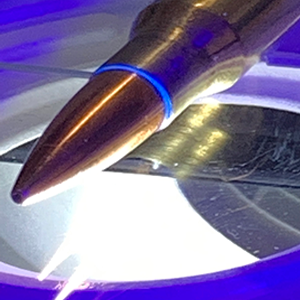

External ammunition sealants for the primer cups and bullet casing joints. Cartridges of the same caliber may have bullets that have the same design but different weights.

Different lacquer and coloured sealants between the primer and the base makes it easy to recognize the cartridges. Colors like red, green, blue, colorless, fluorescent for QM process control.

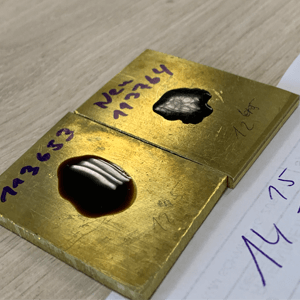

Nato waterproof test according AEP-97

2 options: nitro cellulose based varnish or anaerobic acrylate

Exterior colorless antifriction varnish for better ballistic and protection against saltwater and other contaminants.

It’s available as oven baking varnish or for air drying as anticorrosion varnish too.

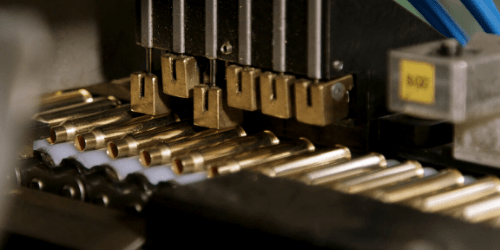

Bitumen based varnish is used to seal the gap between the case mouth and the bullet.

The varnish is assembled by spaying or mechanical stick application by a dipping bath (it depends from the machine construction method) before the bullet is inserted. Different demands on drying time and chemical characteristics like viscosity and elasticity are available.

Certified according TL8010-0024, AEP-97,MIL-C13783C, MOPI, MCSECT 27

Advantages:

- inexpensive product

- high elastically

- absolutely well sealing according Nato standard

- storage stability more than 10 years, don’t crack

- air drying, no UV lights necessary

- no additional process and equipment

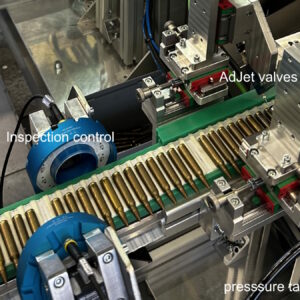

External sealants are single component anaerobic adhesive for sealing the primer and bullet. It improving the bullet pull-out strength and approve the waterproof test according the Nato AEP-97 standard.

It cures in closely fitting joints in the presence of metal and exclusion of oxygen. It has a secondary cure feature which allows the adhesive fillet on the exterior of the gap to be cured via UV light. It`s perfect for high-speed quality control inspections.

- excellent adhesion and capillary performance

- Low viscosity especially for 12.7mm

- improve the bullet pull-out strength

Another method is to coat the bullets with a non-waxy lubricating compound such as nylon, molybdenum disulfide (moly), polymer and other compound.

Coated bullets offer several advantages for hand loaders. Coatings that cover the entire bullet, including the base, reduce or eliminate the exposure to lead during handloading and airborne lead particles when shooting. It also means you no longer have to scrape out built-up wax lube from your seating and crimping dies.

Medium caliber ammunition coatings

We also develop and produce solvent based monolayer baking paints for the exterior and interior of medium caliber ammunition in different colours.

- Exterior antifriction varnish

- Interior antifriction varnish (stanag 4147)